What the Milk Pasteurization Process Is

Milk pasteurization is a standard process that kills harmful bacteria and extends the shelf life of milk products, making them safer for consumption than regular raw milk.

Not only does pasteurization eliminate pathogens that can be found in raw milk, but the process also manages to preserve most of the milk’s flavor and nutritional value, including proteins, vitamins, and minerals. Raw milk and pasteurized milk do taste different, but not so much that it matters to most people.

The most basic understanding of the pasteurization process is that it involves heating milk to a high temperature for a short amount of time and then rapidly cooling it.

Understanding Pasteurization Methods

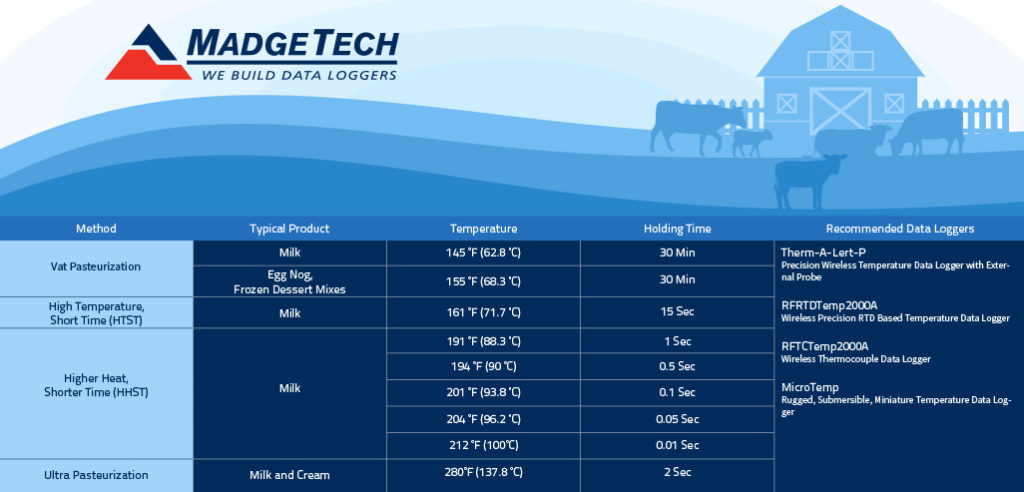

There are several pasteurization methods used in the dairy industry. They tend to be used in different settings based on the volume of milk being produced, what kinds of products the dairy is putting out, what kind of equipment is available, and so on.

Here are the four primary methods: High-temperature short-time (HTST), ultra-pasteurization (UP), and low-temperature long-time (LTLT). The main differences are about how hot you get the milk and how long you keep it at that temperature. Each method has pros and cons. Which one you choose to go with depends on your desired outcomes. Some will yield incredible shelf life, while others will barely change the raw milk from its original form.

Be aware that all pasteurization affects the flavor compounds and nutritional value of milk. This includes the level of vitamin C and other essential nutrients.

Effects of Pasteurization on Milk

Impact on Flavor Compounds

Because pasteurization involves heat, it almost always disrupts the development of subtle flavors. This helps with the standardization of milk, but it can undermine artistic choices. In fact, the heat itself can cause certain tastes that we’ve come to associate with milk. High temperatures can result in more caramelized tastes, while lower temperatures won’t have the same amount of impact.

The flavor compounds are affected by what’s known as the Maillard reaction. This is a chemical reaction between amino acids that reduces sugars.

Changes in Dairy Products

Dairy products can be made from all types of pasteurization methods, including UHT, HTST, UP, and LTLT. However, the method that you choose can affect the quality of your products, depending on what you’re after. For example, if your main product is going to be butter, you won’t want to use UHT method because, as you will read below, it will disrupt the whey proteins and can result in an “off” taste as well as a cream structure that doesn’t want to form.

With any cream-based product, it is crucial that you choose the most stable pasteurization methods so that you can transform the milk even further.

Extended Shelf Life

The main purposes of pasteurization are to 1) remove harmful bacteria, and 2) improve the shelf life and stability of your dairy products. Overall, it’s about safety and convenience.

The different types of pasteurization will result in different extensions of shelf life. The short version is: the higher the temperature, the longer the shelf life. There is a method of pasteurization (UHT) that actually sterilizes the milk and deposits it into an aseptic package for storage. This allows for a shelf life of months. Even at that, however, shelf life is always impacted by how the product is stored (including factors such as humidity, light exposure, and temperature).

Pasteurization and Nutritional Value

Pasteurization is not without side effects. The levels of vitamins, minerals, and proteins are all decreased after heating. The type and duration of pasteurization with cause different levels of impact, but every process results in a change.

The most gentle method is LTLT. Low temperature maintains as much of the milk fat as possible, resulting in a slightly longer shelf life than raw milk and only mildly diminished nutrition.

Types of Pasteurization

High-Temperature Short Time Pasteurization

This is the most common pasteurization method because it yields good results in a short amount of time. Most machinery is equipped for HTST, which involves getting the milk to a temperature of at least 161°F for around 15 seconds.

This method does affect the formation of cream, which means milk that’s been HTST pasteurized won’t be as thick as raw milk, and it won’t whip.

HTST pasteurization is done using a plate heat exchanger, which protects the nutrients of the milk’s components, such as the milk protein and fat molecules. The taste and the quality of the milk are mostly preserved, which means most people don’t mind the outcome.

Low-Temperature Long Time Pasteurization

This method of pasteurization is about preserving as much of the raw milk quality as possible while still removing any harmful bacteria. This typically looks like heating the milk to a temperature of at least 145°F for around 30 minutes.

Most commonly, this method is used for batch pasteurizing. It tends to do the best job preserving the natural flavor of the raw milk, as well as the nutrients, raw cream, and whey proteins. The shelf life is still improved with the LTLT method, which makes this a popular choice among small dairy farmers and local producers.

Another benefit of LTLT is that it can be done with a variety of equipment, which means the requirements are less stringent. Rather than having to send out for a specific piece of machinery, you have options that might be closer to home.

Ultra High Temperature

Ultra-high temperature pasteurization is for milk that needs to be sterilized and stay stable for months at a time. It’s warmed to a very high temperature and then directly deposited into aseptic containers. It extends the shelf life by killing the most bacteria out of all the pasteurization methods. It’s known for keeping milk fresh for a long time.

UHT is typically used for cream, milk, and other dairy products, though it can be used for juices and other beverages. UHT is quick and consistent. It does require hermetically sealed containers for an aseptic process, but after that, your dairy products are shelf-stable for two to three months.

Ultra Pasteurized

Ultra-pasteurized milk is not to be confused with ultra-high temperature pasteurization. UHT is sterile, UP is not. The milk is heated using commercial sterile equipment to 280°F for a minimum of two seconds and then rapidly cooled, but it is not put into hermetically sealed containers, which means it is not considered sterile by food safety standards.

While this method is excellent for turning out high quantities of bottled milk in a short amount of time, it does tend to result in an altered taste. Additionally, because of the extreme heat, ultra-pasteurized milk is not typically suitable for the making of cheese.

Conclusion and Future Directions

Pasteurization is a very important step in keeping your dairy products safe and high-quality. What type of pasteurization you go with is ultimately determined by what your final product will be.

If you want the taste of your milk to be least affected, choosing LTLT is probably your best bet. If you want maximum shelf stability, go with the UHT process and the equipment to match.

The world of dairy and pasteurization is consistently expanding. We’ve listed the four main types of dairy pasteurization, but it’s always important to be up to date on the latest technology, especially when it comes to environmental impact.