Complete solutions for small-scale dairy operations. From pasteurizers to bottling lines, we provide the equipment you need to turn your micro dairy vision into a profitable reality.

Let us help you build your micro dairy operation

The right bottling process can take your liquid dairy products to the next level, allowing you to expand your quality and reach. Good packaging will capture the consumer’s attention while, at the same time, elongating your products’ shelf lives!

One of the ways we provide innovative bottling solutions in the dairy industry and by customizing every machine. Every filler we provide will be adjusted to the bottle sizes and shapes in your production line.

This single valve filler is ideal for small dairy setups and on-farm bottling. The M-2 Manual Milk Bottle Filler doesn’t require electricity, which means it’s easy to install, maintain, and use. It’s low-cost, hygienic, and perfect for farm-fresh sales, pilot batches, and CSA programs.

The M-2 Manual Milk Bottle Filler is ideal for small farm dairies and creameries, on-site milk bottlers, CSA programs, farmers’ market producers, boutique brands, dair labs, and small-batch test facilities.

There are many reasons small dairies across the world are choosing the same machine. The M-2 offers simple installation and operation while maintaining the ability to work with diverse bottle types and shapes. It’s low maintenance and easy to clean, and it’s a space-efficient design that works with your setup. Since it’s fully compliant with US and Canadian dairy standards, it comes ready to use! If you’re anywhere else in the world, we can help get you set up with local regulations.

We ship all over the world, so don’t hesitate to get in touch for a quote, technical specs, or to get answers to your specific questions.

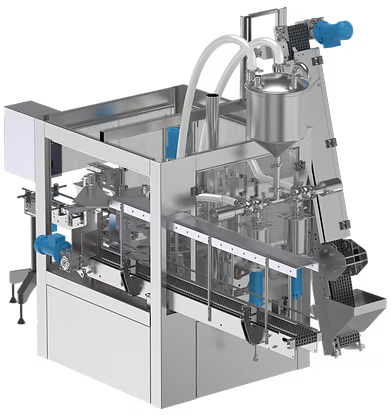

The M-52 is engineered for small to mid-size dairies. The rotary-style, semi-automatic setup aims to scale up your current processes with professional-grade equipment that doesn’t disrupt your work. It features a computer-controlled PLC and HMI, anti-foam valves, and automated filling and capping. This machine delivers clean, exceptional performance while still maintaining that level of flexibility and compact design that small dairies require.

The M-52 Semi-Automatic Milk Bottle Filler is perfect for dairies that need faster output than manual fillers or that don’t have the staff/time to devote to a manual setup. It’s also ideal for processes that require consistent fills with accuracy and consistently sealed caps. Small bottling lines that need compact, high-performing equipment and North American creameries scaling towards automation also find the M-52 to be an exceptional option.

The M-52 has many advantages over other machines. If you need advanced anti-foam technology that ensures clean, air-free fills, this is the machine to go with. It offers fully integrated automatic filling, cap placement, and capping for a hands-free system. The PLC and touchscreen control are easy to use and intuitive. The design is not only compact and made of durable stainless steel, but it also meets the regulatory hygiene standards of the US and Canada.

Don’t wait to contact us for a quote, technical specs, or to discuss your dairy’s unique setup. We ship across the USA, Canada, and worldwide. Call today!

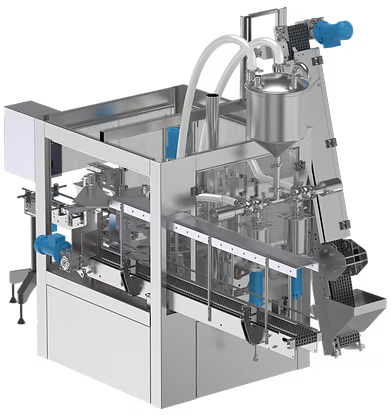

The M-64 Fully Automatic Milk Bottle Filler is highly efficient and built for modern dairies that require a certain amount of output with minimal input. It’s designed to bottle all liquid dairy products in a wide range of volumes. The M-64 handles the entire process with automatic, hygienic precision, controlled by an advanced PLC and boasting anti-foam filling that keeps your process top-tier.

While the other products in this list are for micro dairies, we couldn’t go without listing an option for medium to large-scale dairy plants. If your dairy is producing retail-ready milk and yogurt drinks or if you’re upgrading, the M-64 is for you. With this option, your facilities can achieve consistent output with minimal supervision.

If you do both retail and bulk bottling, the M-64 offers dual-speed flexibility to keep you moving. It has foam-free filling and uniform fills by utilizing overflow nozzles. The integrated cap placement and secure scre capping options mean maximum performance rates. The easy-to-use interface and full process control show you just how intentionally this machine was manufactured for continuous production and regulatory compliance.

If the M-64 sounds like the machine your dairy needs, contact us today! We’re happy to discuss quotes, technical specs, or your situation. We ship worldwide, so don’t hesitate.

Tess Dair Machinery offers machines that put out professional-grade milk bottling but that are still designed for small and mid-sized dairies in the US, Canada, and other countries across the world.

No matter your production needs, whether you’re just starting out with your bottling operation or you’re expanding your current production, our manual, semi-automatic, and automatic milk bottle fillers will do the job well. They deliver consistent and clean results that are compliant with all regulations and are trusted by creameries across the planet.

All the machines we manufacture meet PMO, CFIA, and 3-A sanitary standards. We also always provide easy access to our team and support, as well as worldwide shipping.

Key features of our milk bottling solutions:

In 2025, it’s crucial to consider all aspects of a milk bottle filler for your dairy. You can’t just think about speed and accuracy; you also have to think about hygiene, flexibility, and how easy it is to clean. The market is shifting towards compact solutions that minimize labor and maximize quality, and we’re here for it. From milk to flavored dairy drinks, Tessa Dairy Machinery has top-tier options that meet the strictest standards and provide you with the reliability you’ve been seeking.