Complete solutions for small-scale dairy operations. From pasteurizers to bottling lines, we provide the equipment you need to turn your micro dairy vision into a profitable reality.

Let us help you build your micro dairy operation

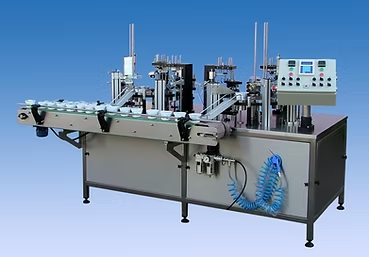

Tessa Dairy Machinery’s cup filling machines are ideal for those seeking hygienic, efficient, and reliable solutions that will streamline their production processes and improve their dairy products. Each of our machines is designed with the strictest industry standards in mind. This includes 3A Sanitary compliance for all fill and seal machines, whether semi or fully automatic. With our help, your dairy products can go to the next level with increased production and extended shelf lives.

A cup filler is a packaging solution using pre-formed cups for liquids. Their widely used in the dairy industry for products such as cream, milk, yogurt, and more. Tessa Dairy Machinery provides options that meet every requirement of production capacity, sanitation, and ease of use. These filling machines simplify the entire process, making them perfect for large or small-scale operations.

The M-4 semi-automatic cup filling machine strikes an incredible balance between automation and manual intervention. If your production needs are flexible and you need an affordable option, the M-4 is just for you.

The M-4 is hygienic, efficient, and precise. The manual cup placement, combined with automatic filling and sealing, ensures that you are involved while still taking the bulk of the work off your shoulders. The pneumatic system and computer-controlled operation mean you can churn out 300-500 cups per hour without sacrificing performance or portioning.

As far as cleanliness goes, the M-4 has a lot of options beat. It’s built entirely from stainless steel and, because of its durability and construction, it’s very easy to clean. It’s also compatible with Clean-in-Place systems. The M-4 has become a trusted choice for small producers who want that balance between quality and quantity.

Key Features:

The M-12 automatic cup-filling machine is fully automatic. It handles cup loading, filling, sealing, and loading, making this an entirely hands-off process. Because of the lack of human intervention necessary, your time is freed up to attend to all the other requirements that come with running a dairy.

This powerhouse of a machine is built for large-scale dairy options. The high-performance automation was designed with precision, hygiene, and speed in mind. It has a production rate of 700-1000 cups per hour while maintaining a 3A Sanitary compliance level.

Key Features:

The M-19 is the highest-producing fully automatic cup-filling machine that we offer. It has a production rate of 1800-2400 cups per hour, making it stand out among its peers. The efficiency, high-quality equipment, and sanitary standards that come with the M-19 make it an ideal choice for dairy farms running a large-scale operation.

The complete automation of the M-19 allows you to provide other services and products while giving you the ability to attend to the other demands of your dairy. Companies that go with the M-19 find that they keep up more easily and their products are of a higher quality than they were before the switch.

Key Features:

The machines we support at Micro Dairy Masters are the highest quality on the market. We have the same commitment to quality, sanitary compliance, and customer satisfaction as Tessa’s Dairy Machinery, making us perfect partners. Together, we’re able to offer you services and products that meet international standards and improve your products.